The FiberCAB (FC) Series is a line of industrial-grade fiber laser cutting systems, offering table size options and laser powers for every metal cutting application.

The FC Series combines the latest developments in fiber laser technology with next generation air- and water-cooled lasers and simple, easy to use CNC controls to make it the most advanced and cost effective industrial-grade cutting system on the market. In designing the FC series, Vytek went beyond building a laser system that only met market requirements. We focus on the real needs of the Fabricator and Manufacturer and the ever-changing production environments with an emphasis on quality production.

The FC Series fiber laser source choices are available in CW water cooled from 1500 watts to 12,000 watts and can achieve highly focused spot density resulting in cutting speeds up to 4 times that of a comparable CO2 laser. In addition, with a focused spot size capability of 10 um (0.0004), incredible detail is possible, even with thicker materials (model dependent).

Users can easily interchange focus heads to the ideal configuration for the job at hand. Heads are available for fine kerf cutting; thick material cutting has an optic focal range from 75 mm to 200 mm.

Ultra-Efficient Fiber Laser Powers

Fiber laser source choices are available in CW water cooled from 1500 watts through 12000 watts or water cooled 150/1500 - 450/4500 watts. Single & Multi-Mode (Laser power dependent) with wavelengths of 1070-1080 um.

Positioning System

The Positioning System uses dual guide ways on either side of the gantry and is driven by the high-grade ground ball screws combined with glass linear encoders for true position accuracies (model dependent).

Motion Controls

The Latest Generation controls use high performance brushless servo drives, which are directly coupled to Vytek’s simplicity CNC control, ensure the smoothest possible motion for the most demanding part geometries.

Keypad

The FC includes a rugged keypad, which features a full graphic display. The operator keypad allows for machine control and is the central point for operation. It displays all critical job information and allows for on-the-fly edits to the program.

Programmable Gas Assist Controls

Air assist is essential to the perfect cut. Nitrogen and Oxygen are used primarily but occasionally shop air is also used. The air assist would require 22 BAR – 325 psi.

All Steel Base Structure

The Base Structure and the heart of the system is a precision ground structure mated to all steel and ground gantry/bridge assembly. By ensuring the X, Y and Z planes of the base structure and gantry are geometrically correct to each other there is no need to compensate or use complex correction algorithms to adjust for a poor design or construction.

Standard Table Configuration

Our Modular Table design allows for easy access to the surface while maintaining the smallest possible footprint.

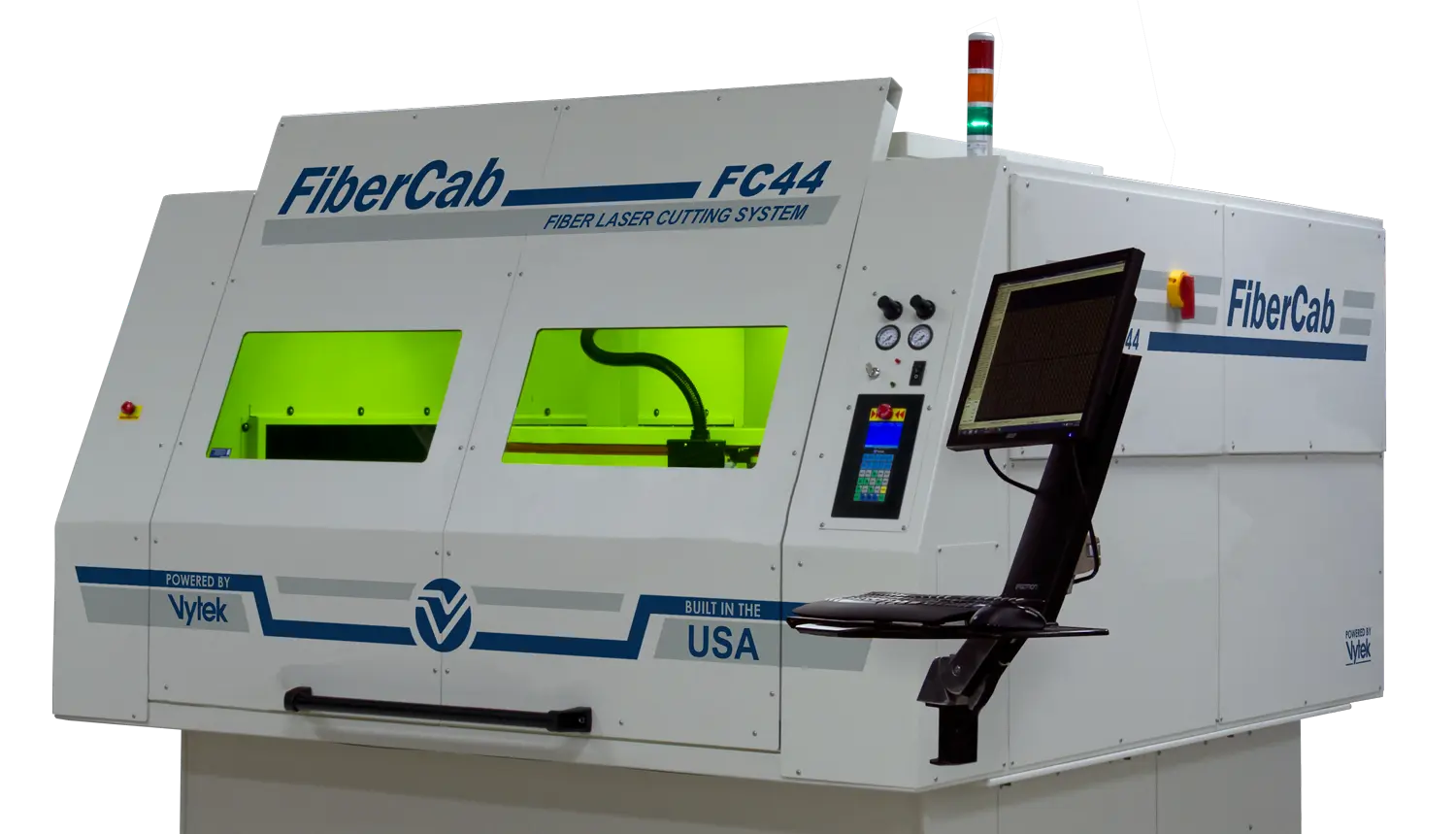

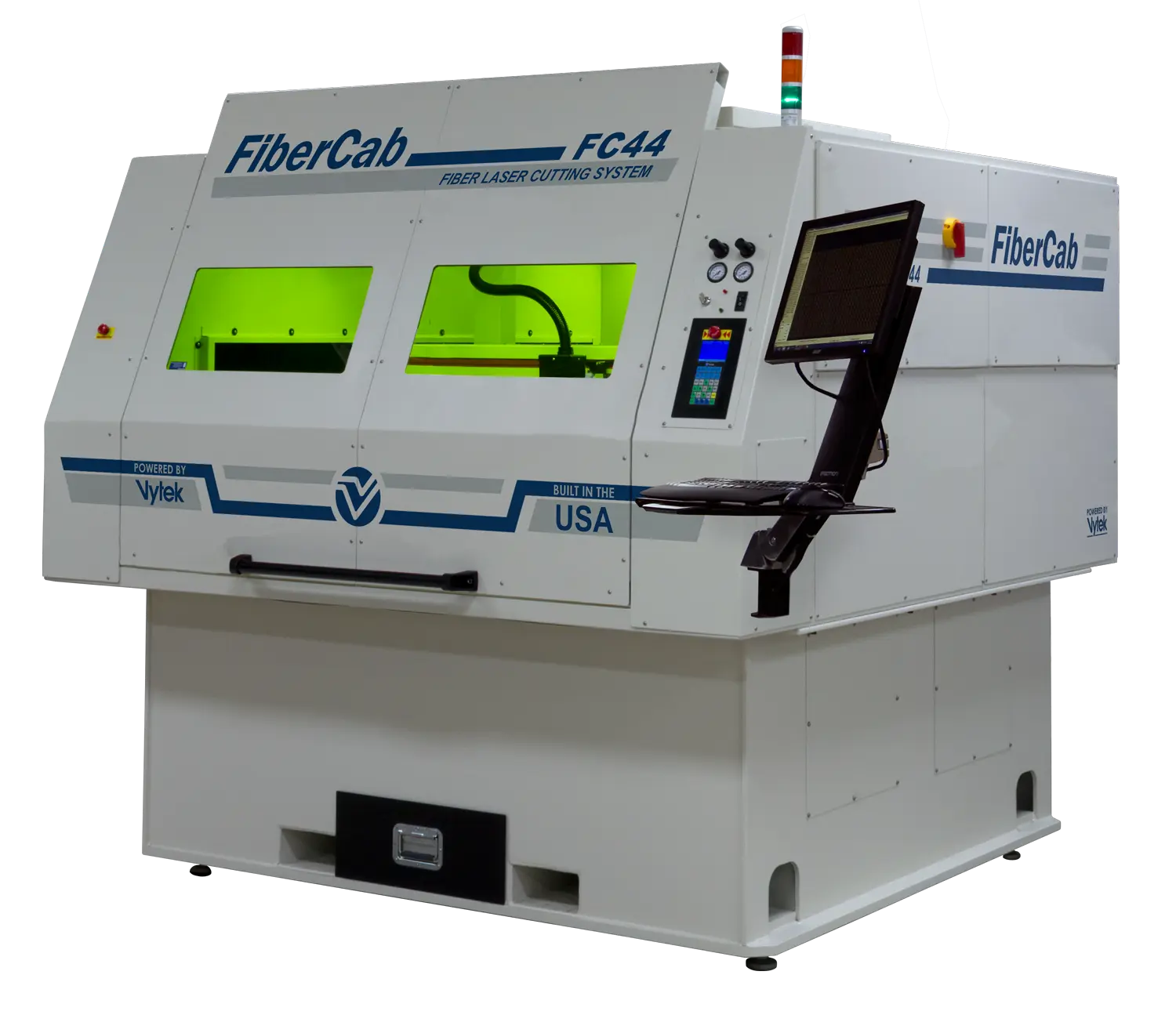

FC44

The FC44 packs a real punch while being perfectly sized for the small shop and highly detailed work. The FC44 uses advanced drives allowing for blazing speeds and high throughput when cutting complex geometries.

FC48

The big brother of the FC44 is our FC48, perfect for the shop with space limitations, but still wanting to be able to cut full-sized sheets. The FC48 has an oversized work area of 4′ x 8′ so larger parts are easily accommodated.

FC510

The FC510 is designed for the manufacturer and job shops who have the space and capacity for larger materials. It can accommodate full 5x10 sheets. The FC510 has the option for an additional 2' in length.

Max Load Weight

1,000 lb.

Axis Stroke

1300 mm (51″) x 1300 mm (51″)

Repeatability

.015mm (.0005″)

Drive Feed Method

Precision Ground Ball Screw

Table Dimensions w/o pallet changer (L x W x H)

4' x 8' x 36" (1219 mm x 2438 mm x 910 mm)

Table Dimensions w/o pallet changer (L x W x H)

4' x 4' x 36" (1219 mm x 1219 mm x 910 mm)

Table Dimensions w/o pallet changer (L x W x H)

10' x 5'' x 36" (1524 mm x 3048mm x 910 mm)

Max Load Weight

2,000 lb.

Max Load Weight

2,000 lb.

Axis Stroke

1300 mm (51″)

x 2500 mm (98″)

Axis Stroke

1575 mm (62″) x 3100 mm (122″)

Repeatability

.05mm (.002″)

Repeatability

.05mm (.002″)

Drive Feed Method

Precision Ground Ball Screw

Drive Feed Method

Rack & Pinion & Ball Screw

Table Options

4"/100mm Moving Spindle Rotary Tube Cutting Option

• Accommodates round, square and rectangular with a diameter up to 4"

• Base mounted extension frame for up to 8' feet of continuous tube feeding

• 12" self centering 4 jaw chuck, 4" through hole on a moving slide assembly

• Adjustable rotating tube fixture for round square and rectangular tube

• Re-chucking allows feeding of up to 24' in tube length with support of tube

3"/75mm Fixed Spindle Rotary Tube Cutting Option

• Accommodates round, square, rectangular to 3" in diameter

• Mounted on base allowing 7' feet of tube length to be cut

• 10” self centering chuck with a 3" through hole

• Includes adjustable tailstock for support

2.5"/60mm Fixed Spindle Rotary Tube Cutting Option

• Accommodates round, square, rectangular to 2.6" in diameter

• Mounted on base allowing up to 7' feet of tube to be cut

• 8” self centering 4 jaw chuck with a 2.6" through hole

• Includes adjustable tailstock

1.5"/38mm Table Mounted Rotary Tube Cutting Option

• Accommodates tube in round, square, rectangular to 1.6" in diameter

• Removable table mounted allowing up to 7' feet of tube to be cut

• 6” self centering 4 jaw chuck with a 1.6" through hole

• Includes adjustable tailstock

Shuttle Table

• Single or two drawer shuttle tables

• Manual or fully automatic

Software Options

I-Laser Vision PLUS Alignment System

• For auto alignment of sheet and pre-cut parts

• Head mounted high resolution camera with lighting

Regulator Options

Gas Regulator for Medium Pressure Oxygen

• Medium pressure gas regulator for use with gas or liquid assist gas

Gas Regulator for High Pressure Nitrogen

• High pressure gas regulator for use with gas or liquid assist gas

Programmable Gas Pressure Option

• Allows assist gas pressures to be programed in job process

• Requires low pressure Nitrogen for operation

Dust Extraction Options

5.5kW 4 Filter Self Contained Dust Extraction Unit

• Exchanges inside air using 4 filter cannisters

• Requires Filter Replacement based on Frequency of Use